Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

June July 2006 Vol. 8 issue 5<br />

<strong>Forestry</strong><br />

<strong>Access</strong><br />

Industrial<br />

Lifting & <strong>Access</strong><br />

Loader<br />

Cranes<br />

2006<br />

UK/Ireland<br />

Dealer & Source Guide<br />

The LARGEST UK CIRCULATION of any lifting equipment magazine<br />

www.vertikal.net<br />

£8

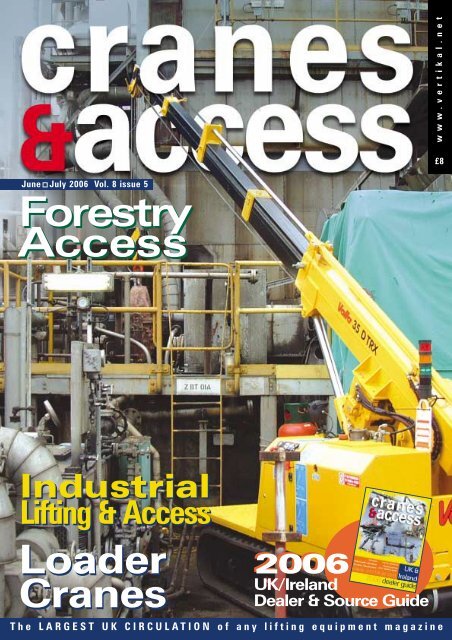

On the<br />

cover:<br />

A Valla TX35 rubber tracked,<br />

pick and carry crawler crane,<br />

proves to be ideal for refinery<br />

maintenance tasks, such<br />

as replacing pumps and<br />

turbine fans.<br />

16<br />

23<br />

56<br />

Lorry Loaders<br />

Micro lifts<br />

<strong>Forestry</strong> Lifts<br />

SUBSCRIPTIONS: Cranes & <strong>Access</strong> is published eight times a year<br />

and is available on payment of an annual subscription of £40.00.<br />

If you wish to subscribe, please send a crossed cheque made<br />

payable to The Vertikal Press Ltd to: Subscriptions, The Vertikal<br />

Press, PO Box 6998, Brackley, Northants NN13 5WY. Address<br />

changes should also be sent to this address. Please include the<br />

address label from a recent issue with all correspondence and allow 3<br />

months for changes to be effective.<br />

SUBSCRIBE ONLINE AT:<br />

www.vertikal.net/en/journal_subscription.php<br />

BULK DISCOUNTS: These are available to companies wishing to<br />

take out multiple subscriptions. Please contact the subscriptions<br />

manager for more details.<br />

Tel: +44 (0)8707 740436 Fax:+44 (0)1295 768223<br />

E-mail: info@vertikal.net<br />

Kran & Bühne: The Vertikal Press also publishes a German<br />

magazine which deals with the same issues as Cranes & <strong>Access</strong>,<br />

but is written for German users and buyers. Details available<br />

on request.<br />

While every effort is made to ensure the accuracy of information<br />

published in Cranes & <strong>Access</strong>, the Editor and Publisher can accept<br />

no responsibility for inaccuracies or omissions. Views expressed in<br />

articles are those of the authors and do not necessarily reflect<br />

those of the Editor or Publisher. Material published in Cranes &<br />

<strong>Access</strong> is protected under international copyright law and may not<br />

be reproduced without prior permission from the publishers.<br />

Comment 5<br />

News 6<br />

Quigley becomes<br />

Quigley, UpRight to move<br />

production to the UK,Liebherr<br />

starts telehandler production, John<br />

Deere quits telehandler market, Fork Rent enters<br />

access market, Platform company place £30<br />

million order with Genie, Terex discloses spec<br />

on AC100-4 how does it stack up?, Liebherr<br />

to launch new 130 tonne five axle AT, Vanson<br />

launches trapezoidal topless tower crane,<br />

new mini cranes from Imai, Leith Docks fined<br />

£200,000, Allan <strong>Access</strong> introduces a 20<br />

metre boom on a Ford Transit.<br />

Lorry Loaders 16<br />

Mark Darwin finds out more about<br />

Travis Perkins and how it manages its fleet<br />

of over 1,000 cranes. Plus a roundup<br />

of what’s new on the market.<br />

Lighter, Smaller,<br />

Cheaper 23<br />

We look at the market for the smallest self<br />

propelled lifts, designed for work in the most<br />

compact areas and to travel in the smallest<br />

elevators. With mast type lift mechanisms<br />

which is best, aluminium or steel?.<br />

Its Plant Shutdown<br />

time 28<br />

Our annual review<br />

of access and lifting<br />

products and methods for<br />

the annual manufacturing<br />

plant shutdown period. We include job reports<br />

on some challenging machinery removals and<br />

installations in restricted headroom situations.<br />

The 2006 C&A<br />

UK/Ireland dealer<br />

and source guide 35<br />

Our eight page pull out dealer guide provides<br />

a comprehensive listing of suppliers of all<br />

types of access and lifting equipment.<br />

In the next C&A<br />

Top 20 yes it is our annual top 20 UK/Ireland crane, access<br />

and telehandler rental companies. Entry forms will be emailed<br />

and faxed out in late July. Alternative and heavy lifting and<br />

truck and van mounts, plus the 2006 Vertikal Check, this<br />

years 15/16m spider lifts.<br />

c&a<br />

contents<br />

Face to Face 43<br />

Pam Penny visits Bob<br />

Francis crane hire and talks<br />

to Bob and Mark Francis<br />

about the company’s new<br />

Manitowoc 8500E.<br />

SED 45<br />

This year the UK’s big equipment show, SED,<br />

opened the doors to its 40th show at a new<br />

location in Corby, We present some of the<br />

highlights in our three page review.<br />

Peter Oram<br />

1937 – 2006 52<br />

<strong>Access</strong> for<br />

<strong>Forestry</strong> work 56<br />

Mark Darwin talks to tree surgeons and<br />

learns how the increasing use of powered<br />

access is making the work faster and safer,<br />

but also how a lack of guidance is causing<br />

accidents with the equipment.<br />

For the Record 63<br />

How Bovis Lend Lease helped<br />

improve tower crane safety in the UK<br />

regulars<br />

Innovations 51<br />

ALLMI focus 53<br />

Training 55<br />

Letters 60<br />

IPAF Focus 61<br />

Web links 64<br />

What’s on/<br />

event guide 65<br />

June July 2006 cranes & access<br />

3

cranes<br />

&access<br />

For users & buyers of lifting equipment<br />

The Vertikal Press<br />

PO box 6998 Brackley NN13 5WY. UK<br />

Tel: +44(0)8707 740436 Fax: +44(0)1295 768223<br />

email: info@vertikal.net<br />

web: www.vertikal.net<br />

In Germany:<br />

Vertikal Verlag<br />

Sundgaualle 15, D-79114,<br />

Freiburg, Germany<br />

Tel: 0761 8978660 Fax: 0761 8866814<br />

email: info.vertikal@t-online.de<br />

web: www.vertikal.net<br />

Germany, Scandinavia,<br />

Austria and Switzerland<br />

Karlheinz Kopp, Vertikal Verlag,<br />

Sundgaualle 15,D-79114, Freiburg, Germany<br />

Tel: +49 (0)761 89786615<br />

Fax:+49 (0)761 8866814<br />

email: khk@vertikal.net<br />

Italy<br />

Fabio Potestà, Mediapoint,<br />

Corte Lambruschini,<br />

Corso Buenos Aires 8, V Piano-Interno 7,<br />

I-16129 Genova, Italy<br />

Tel: 010 570 4948 Fax: 010 553 0088<br />

email: mediapointsrl.it<br />

The Netherlands<br />

Hans Aarse<br />

39 Seringenstraat, 3295 RN,<br />

S-Gravendeel, The Netherlands<br />

Tel:+31-78 673 4007 Mobile:+31(0) 630421042<br />

email: jfwaarse@planet.nl<br />

UK and all other areas<br />

Pam Penny<br />

PO box 6998 Brackley NN13 5WY. UK<br />

Tel: +44(0)8707 740436<br />

email: pp@vertikal.net<br />

Design & Artwork by:<br />

bp design Ltd.<br />

Tel: 01707 642141 Fax: 01707 646806<br />

email: studio@bpdesign.info<br />

ISSN: 1467-0852<br />

© Copyright The Vertikal Press Limited 2006<br />

The Vertikal Press also publishes:<br />

June July 2006 Vol. 8 issue 5<br />

Editors:<br />

Leigh Sparrow<br />

Mark Darwin<br />

Associate Editors:<br />

Ian Boughton<br />

Rüdiger Kopf<br />

Alexander Ochs<br />

Sales & customer support:<br />

Pam Penny<br />

Karlheinz Kopp<br />

Production:<br />

Nicole Engesser<br />

Publisher:<br />

Leigh Sparrow<br />

The Vertikal Press Ltd.<br />

MEMBERS OF<br />

Letters, emails, faxes and<br />

phone calls are welcome and<br />

should be sent to:<br />

The Editor,<br />

cranes & access,<br />

PO Box 6998, Brackley<br />

NN13 5WY, UK<br />

Tel: +44(0)8707 740436<br />

Fax: +44(0)1295 768223<br />

email: editor@vertikal.net<br />

Zealots are not helping<br />

Few in the lifting world would disagree with<br />

the notion that safety is far and away the<br />

most important aspect of what we do.<br />

Yet there are still way too many accidents<br />

that could be prevented and at the recent<br />

crane safety conference Bryan Cronie of<br />

Mammoet said: “Contractors are only interested in the cheapest price” and<br />

that “competitive tendering for work is the base of the evil”.<br />

Cranes & <strong>Access</strong> takes serious issue with this statement. No one wants an<br />

unsafe site because no contractor can afford the price of an accident. No matter<br />

how much is saved on a heavy lift contract or on the hire rates paid for equipment,<br />

it pales into utter insignificance compared with the cost of an accident.<br />

We believe that elements within the safety industry are now guilty of slowing<br />

up improvements in site safety in the western world. There are many passionate<br />

and effective people involved in safety; and make no mistake about it, it is a<br />

big business these days. However, it seems that among them are a good<br />

number of misguided zealots who are influential way beyond their number.<br />

Instead of encouraging the wider adoption of safe practices and working with<br />

contractors, rental companies and equipment manufacturers in a positive and<br />

practical way, the zealots seem driven by a mission to write new rules and<br />

catch people out. Rather like the policeman who hides in the bushes to catch<br />

a speeding car rather than making the road a safer place by slowing traffic<br />

at black spots.<br />

Some examples?<br />

• Excessive paperwork: Cronie referred to two identical lifts, one in Canada<br />

with a 12-page method statement, while the one in the UK was<br />

151 pages long. One was written for the zealots and rear-end cover,<br />

while the other, simpler one, was there to help ensure a safe lift.<br />

• Impractical lengths for basic operator courses, five or six days, when two or<br />

three might be more than sufficient, so fewer people receive proper training.<br />

• Slavish adoption of high-visibility “safety” measures such as fluorescent<br />

jackets and helmets, which can distract from higher risk issues.<br />

• Misguided regulators who consume valuable committee time to push<br />

non-issues such as drop bar gates on aerial lifts, rather than tackling real<br />

issues such as harness wearing on boom lifts or removing overload<br />

devices on scissor lifts.<br />

The zealots not only fail to make the world a safer place, but they can bring<br />

safety rules into disrepute and create an unholy alliance of employees and<br />

employers against safety officers.<br />

This is a subject way too big for this comment page, we will be covering<br />

this in more detail in future issues, please send us your views to<br />

“Stop the Zealots” c/o lws@vertikal.net<br />

Leigh W Sparrow<br />

c&a<br />

comment<br />

June July 2006 cranes & access<br />

5

news c&a<br />

The first glimpse at the Liebherr<br />

TL435-13 telehandler to be<br />

launched at Bauma 2007<br />

First Liebherr<br />

Telehandlers shipped<br />

Following an extended test and<br />

evaluation period, Liebherr has started<br />

producing and shipping its first telescopic<br />

handlers within what it considers to be<br />

its domestic market area of Germany,<br />

Switzerland and Austria. Up to 60<br />

Liebherr TL4 series of telescopic<br />

handlers are currently at work. The TL4<br />

is the first model range or family, in<br />

what has been a long expected entry<br />

In an interview with a Japanese<br />

industrial magazine, the president<br />

of Aichi discussed future plans to<br />

significantly expand its overseas<br />

market shareing Include a five fold<br />

increase in European and North<br />

American sales, aiming to reach or<br />

exceed sales of 28.5 billion yen<br />

($250/€200/£135 million) by 2011.<br />

The company has also said that<br />

it will be looking to add production<br />

facilities in North America<br />

and Europe.<br />

Outside its home market Aichi,<br />

concentrates its efforts on selling its<br />

ultra high quality track and wheel<br />

mounted self propelled straight boom<br />

6<br />

cranes & access June July 2006<br />

by Liebherr into this market. The series<br />

will have three regular models with<br />

two 10 metre models and a 13 metre<br />

with capacities of 3,500 and 4,200 kgs.<br />

A 10 metre, 4,500 kg industrial model,<br />

the TL4 45/10, will also be available.<br />

The official international launch<br />

of the TL4 series is likely to be<br />

at Bauma, in Munich next spring.<br />

Aichi aims for 500%<br />

growth in USA and Europe<br />

lifts. While the company commands<br />

a premium price for its boom lifts,<br />

it has quietly secured a surprisingly<br />

large share of the market, thanks to<br />

a standard five year warranty and<br />

low ownership costs.<br />

Aichi’s scissor lifts in Japan, have<br />

largely not suited the European<br />

market and have been more<br />

expensive than the market will bear.<br />

However the interview indicates that<br />

the company is preparing to launch<br />

a new range of products, including<br />

articulated booms and scissor lifts,<br />

targeted at the European and North<br />

American markets. It says that the<br />

units will be priced competitively<br />

with local products.<br />

As part of its mid term plan which<br />

began this year, Aichi has opened a<br />

new sales office in the USA and it is<br />

relocating its European manger Yasua<br />

Saito from Japan to its European<br />

base, south of Breda in Holland. Aichi<br />

management declined to comment or<br />

add to the points raised in the interview.<br />

Aichi intends to break out into<br />

the wider aerial lift market.<br />

Quigley and Quigley<br />

On May 12th Quigley United<br />

Kingdom Ltd, the highly leveraged<br />

UK crane hirer, finally appointed<br />

an administrator following weeks<br />

of rumours. Within what might<br />

have been a mere nanosecond;<br />

the business was purchased by<br />

Quigley UK Lifting Services, with<br />

exactlt the same owners and<br />

directors, Shaun and Gary Quigley.<br />

The administrator, initially Mathew<br />

Colin Bowker and S Payne and then<br />

later Brendan Hogan all of Unity<br />

Business Services LLP of Bolton<br />

Lancashire, said in a letter to creditors<br />

“The purpose of the appointment is<br />

to achieve a better result for the<br />

company’s creditors as a whole<br />

than if the company were wound up”<br />

How an obviously pre-agreed sale<br />

works in any creditor’s favour has<br />

never been explained.<br />

The flagship of the Quigley fleet, the 700 tonne Terex Demag AC700SSL, dubbed<br />

the 850 tonne AC2100 by Quigley, is the last machine to be sold. As of the first<br />

week of July, Terex Demag was in discussions with a number of buyers.<br />

Lavendon adds A.M.P<br />

The Lavendon group, owner of Nationwide <strong>Access</strong> and Europe’s largest<br />

powered access rental company, added a third regional rental company<br />

to its portfolio in June, snapping up Taunton based A.M.P. The company<br />

was owned by chairman Mike Boyle and his family, Paul Onslow and<br />

managing director Andy Pearson. As with Panther platform rentals and<br />

Kestral were acquired in February, the managers will remain in place<br />

and continue to operate under the A.M.P brand.<br />

A.M.P has a fleet of 525 units, four locations, in Taunton, Liskeard, Gloucester<br />

and Poole - a location it acquired from Newlins - and 57 staff.<br />

Revenues through 31 August 2005 were £4.8 million with a pre tax profit of<br />

£1 million. It has gross assets of £6.3 million and net assets of £2.6 million.<br />

Revenues for the past 12 months are up to £4.9 million with a pre tax profit<br />

of £600,000.<br />

Lavendon paid £3 million in cash for the business with an extra £300,000 to<br />

£2.6 million in cash available dependent on A.M.P’s performance over the next<br />

two years. In addition Lavendon assumed A.M.P’s net debt of £2.8 million,<br />

making the deal worth £5.8 million up front and £7.4 million if the management<br />

team can achieve the pre agreed results over the next 24 months.<br />

A.M.P, like Panther, was a very active member of the <strong>Access</strong> Link, the association<br />

of regional access hirers that work together to provide a national coverage of<br />

consistent quality.<br />

Mike Boyle and Andy<br />

Pearson of AMP will<br />

manage the business<br />

under Lavendon<br />

ownership<br />

Most, if not all of Quigley’s cranes<br />

were heavily financed and were<br />

quickly repossessed thanks to the<br />

buoyant market for used cranes.<br />

This has left the new company<br />

struggling but still pressing on.<br />

Questions have since been raised<br />

concerning a number of transactions<br />

between the old Quigley and the new.<br />

The Quigley’s have a long boom and<br />

bust history in the crane business.<br />

Their father Jimmy Quigley ran<br />

Overmile Crane Hire, Jubilee Crane<br />

Hire, Dixons Crane Hire and then<br />

Dixons Universal Crane Hire which<br />

was acquired by Baldwins in the<br />

mid 90’s. The two sons initially<br />

joined Baldwins but did not stay<br />

long. Instead they teamed up with<br />

Roger Taylor and David Symon,<br />

where they honed their skills.

Kranlyft enters the rental market<br />

Kranlyft, the Maeda and Kato cranes distributor across Europe, has entered<br />

the UK mini crane rental market. The company is starting off with 10 or 11<br />

new cranes and has appointed Alan Peck as general manager of its hire<br />

division. Peck was previously with Speedy Hire’s, lifting division.<br />

Peck told C&A that the company hoped to have between 15 and 20 units in<br />

the fleet by the end of the year. The move into rental will coincide with the<br />

company’s move to a new purpose built,1,350 square metre facility in Avonmouth.<br />

Kranlyft has also appointed Caledonian Cranes of Glasgow and Aberdeen,<br />

as its distributor for Scotland. John Stalker of Caledonian said that it plans<br />

to follow Kranlyft's new strategy, both renting and selling mini cranes.<br />

Full story see www.vertikal.net<br />

Fork Rent, the Ipswich based<br />

telehandler rental company,<br />

that ordered 1,000 new JCB<br />

telehandlers in April, has<br />

purchased 25 Manitou rough<br />

terrain boom lifts for its fleet,<br />

through Russon access, the<br />

Mani<strong>Access</strong> dealer. Most units<br />

are the 521ft platform height<br />

180ATJ, model fully equipped<br />

with articulating jib, four wheel<br />

drive and four wheel steer.<br />

Guy Nicholls managing director of<br />

Fork Rent said that it had frequent<br />

requests from its customers for<br />

aerial lifts and had decided that<br />

now was a good time to enter the<br />

market. He said that most of the<br />

company’s customers needed<br />

heavy duty rough terrain equipment.<br />

Chairman Trudi Nicholls told C&A<br />

that the company had found<br />

Russon <strong>Access</strong> to be an easy<br />

company to deal with a good<br />

attitude. She also said that the<br />

booms were going out on hire as<br />

fast as they were being delivered.<br />

Alan Peck<br />

and Terry<br />

Marnock of<br />

Kranlyft UK<br />

with John<br />

Stalker of<br />

Caledonian<br />

Cranes<br />

Fork Rent enters access market<br />

Alan Russon (R) with Guy<br />

Nicholls of Fork Rent,<br />

and one of<br />

its 180ATJ<br />

boom lifts<br />

......And the<br />

crane market.<br />

In addition to the access market,<br />

Fork Rent is dipping its toe in the<br />

self erecting tower crane market<br />

with the purchase of a single FB<br />

Gru self erector from Hos plant.<br />

The unit was on display at the<br />

recent SED show.<br />

c&a<br />

John Deere is to withdraw from<br />

the telehandler market and has<br />

announced that its Zweibrücken<br />

factory in Germany will discontinue<br />

the manufacture of telescopic<br />

handlers, at the end of October 2006.<br />

The company says that the<br />

Zweibrücken factory will continue<br />

its role as the company’s European<br />

centre for the design, manufacture<br />

and support of harvesting<br />

equipment.<br />

The company's decision, it says,<br />

follows a detailed assessment of<br />

worldwide market conditions and<br />

the business environment, as well<br />

as consideration of potential<br />

alternatives. It will not affect<br />

permanent employment at the<br />

Zweibrücken factory or at other<br />

June July 2006 cranes & access<br />

news<br />

John Deere is<br />

quitting the<br />

telehandler market.<br />

John Deere pulls out of Telehandlers<br />

John Deere factories supplying<br />

telescopic handler components.<br />

John Deere and its dealers will<br />

continue to provide customers with<br />

full parts and product support for<br />

current and previous telescopic<br />

handlers, including both 3000<br />

and 4000 Series models. Further<br />

information on the decision has<br />

been limited, but it seems that the<br />

company has no plans to try and<br />

sell the product designs or to<br />

badge another manufacturer’s<br />

products as its own. John Deere<br />

failed to capture any significant<br />

share of the telehandler market,<br />

and is understood to have been<br />

loosing money on every one sold.<br />

Its greatest success was in the<br />

UK, but even here, market share<br />

percentages barely registered.<br />

7

news c&a<br />

James Ainscough (L) and Lorraine Lockie-Gorvins prepare to launch the balloon<br />

race for ‘Go Yellow’ day.<br />

Ainscough goes Yellow<br />

Ainscough Crane Hire’s Manchester depot was contacted by St Ann’s<br />

Hospice and Stockport based law firm Gorvins Solicitors to provide a crane<br />

for their yearly fund raising campaign ‘Go Yellow’. Every June the hospice<br />

encourages local businesses to ‘Go Yellow’ for the day to raise money to<br />

help fund the Manchester Hospice. This year, St Ann’s thought that a shiny<br />

yellow Ainscough Crane would be ideal for the launch of its balloon race.<br />

8<br />

cranes & access June July 2006<br />

Loxam takes on<br />

Spreeuwenberg<br />

Loxam the French based rental group, one of the largest two equipment<br />

rental companies in Europe, has purchased Rotterdam based<br />

access company, van Spreeuwenberg Hoogwerk Systemen B.V.<br />

Loxam declined to disclose how much it paid for the company.<br />

Spreeuwenberg, established in 1974 as a scaffold and ladder rental company<br />

know specialises in Alloy tower, ladder and aerial lift sales and rental.<br />

The company has six locations, four of which are sales and rental outlets,<br />

in Amsterdam, Den Bosch, Rotterdam and Zwolle. Its fleet is estimated to<br />

be around 800 to 900 units.<br />

Loxam now operates in eight countries, this will be its largest operation<br />

outside of France and replicates its UK/Irish business, where it is an<br />

access specialist rather than a general rental company.<br />

Certex to distribute Demag<br />

Certex UK has been appointed as a UK distributor for Demag Cranes<br />

and Components Ltd, (Overheads and hoists etc... not Terex-Demag<br />

mobiles) taking over the accounts of 300 smaller Demag customers.<br />

Certex will take over the supply of Demag products and spare parts<br />

to these customers.<br />

Demag will continue to supply its<br />

cranes, hoists and spares to its<br />

key account customers in the UK.<br />

See Vertikal.net for full story<br />

Tarik Alkhalil sales director of Demag<br />

UK.(L) with Charles Gillespie, sales<br />

and marketing director, Certex

Hiab’s Moffett Engineering has<br />

signed a license based cooperation<br />

agreement with Combilift Ltd, the<br />

fork lift company based in Clontibret,<br />

Ireland. The agreement covers<br />

‘know-how’ and gives Moffett the<br />

right to manufacture and sell a new<br />

telescopic ‘Telemount’ truck-mounted<br />

forklift developed by Combilift.<br />

Dubbed the ‘Moffett-Telemount’ it<br />

will be manufactured at Moffett’s<br />

Dundalk plant in Ireland and sold via<br />

Egi acquired<br />

Egi the specialist truck mounted aerial<br />

lift supplier, based in Northern France<br />

has been acquired by fire fighting<br />

vehicle specialist Gimaex. Gimaex owns<br />

Echelles Riffaud, the long-established<br />

manufacturer of fire ladders, along<br />

with Gicar which produces fire tender<br />

vehicles, largely for airport operations<br />

and Bemaex, a specialist producer of<br />

emergency vehicles and equipment.<br />

A Moffett rough terrain<br />

piggy-back fork lift<br />

Moffett to introduce piggy-back telescopic handler<br />

the Hiab-Moffett distribution network<br />

this autumn.<br />

The companies have also agreed<br />

on future Research & Development<br />

co-operation within the truck mounted<br />

forklift market. Hiab says that the<br />

agreement will strengthen its offering<br />

and know-how in truck-mounted forklifts.<br />

Moffett has also expanded production<br />

capacity with a new production facility<br />

at its Dundalk location.<br />

JCB doubles profits<br />

JCB has announced record sales and profits for its fiscal year 2005. The company<br />

produced 45,000 units, up 21 percent on 2004, while sales jumped by 23 percent<br />

to £1.42 billion. JCB says that during the year it moved up from fifth place,<br />

among the world’s construction equipment manufacturers, to fourth as its<br />

market share increased by a full percentage point to 9.6 percent.<br />

JCB is still a private company and as such does not release detailed financials,<br />

but it says that profits doubled, from £55 million in 2004 to £110 million in 2005.<br />

Demag IPO disappoints<br />

Demag Cranes initial public offering<br />

raised €235 million, substantially<br />

less than the €500 million that was<br />

predicted the week before its flotation.<br />

Just over half of the 16.9 million<br />

available shares were taken at €22 a<br />

share. It was thought they might reach<br />

€31. Demag’s owners, Kohlberg Kravis<br />

Roberts & Co. and Siemens AG planned<br />

to sell 70 percent of their shares.<br />

Ashtead achieves new records<br />

The Ashtead group, owner of Sunbelt Rentals and A-plant, and the world’s<br />

fourth largest rental company, has reported a record year in 2005/06.<br />

The company saw revenues rise by almost 22 percent, while pre-tax profits climbed<br />

by more than 250 percent to £81.7 million. The company says that if distortions and<br />

exceptionals are taken out of the equation ‘underlying profits’ more than tripled.<br />

…And George Burnett announces his retirement<br />

At the same time Ashtead CEO and joint founder of the Ashtead group, George<br />

Burnett (along with Peter Lewis) has announced that<br />

he will retire after his 60th birthday in September.<br />

His replacement has been named as Geoff Drabble,<br />

currently an executive director of The Laird Group.<br />

Burnett will work with Drabble until the end of the year.<br />

George Burnett, CEO of Ashtead<br />

will retire later this year<br />

June July 2006 cranes & access<br />

9

news c&a<br />

MX19 Micro Scissor<br />

Superior Powered<br />

<strong>Access</strong> From The<br />

World’s Leading Experts<br />

The MX19 from UpRight Powered <strong>Access</strong> is the original microscissor<br />

lift and remains the professional’s choice the world over.<br />

This ultra-compact, self-propelled machine has an extremely<br />

tight turning circle - providing superb manoeuvrability, yet<br />

still offering a safe and effective working height of 8 metres.<br />

Standard features include non-marking tyres and a roll-out deck<br />

extension for extra platform space where it is really needed.<br />

Other features at no extra cost include:<br />

• One hand proportional controls<br />

for smooth operation<br />

• Power line to platform<br />

• Low battery voltage indicator<br />

• Warning horn<br />

Our commitment to innovation means the<br />

MX19 remains the original and still the best.<br />

10<br />

Sales:<br />

Tel: + 353 1 620 9343<br />

Fax: + 353 1 620 9301<br />

cranes & access June July 2006<br />

Spares & Parts:<br />

Tel +44 (0) 1952 685 200<br />

Fax +44 (0) 1952 685 255<br />

Headquarters: UpRight Powered <strong>Access</strong>, Tanfield Lea Industrial<br />

Estate North, Stanley, Co. Durham, DH9 9NX, U.K.<br />

Tel: +44 (0) 1207 521 111 Fax: +44 (0) 1207 523 355<br />

www.upright.com<br />

Platform Company<br />

spends £30 million<br />

on Genie<br />

The Platform Company<br />

has placed a £30 million<br />

order with Genie for<br />

new self propelled lifts.<br />

The order covers models<br />

from the GS1932, 19ft<br />

scissor lift up to the<br />

S125, 125ft straight boom.<br />

All diesel powered<br />

lifts will include on-board<br />

240v generators,<br />

providing users with a<br />

self-contained power<br />

source for tools and<br />

equipment. Deliveries<br />

under this ‘preferred<br />

supplier programme’<br />

have already started.<br />

More big booms for<br />

Nationwide<br />

Nationwide has spent £1.3 million on 17 more big Genie booms. The<br />

machines which have already been delivered include three 85ft straight<br />

boom S85s, 10 number 80ft articulated boom Z80/60s and four Z135s -<br />

Genie’s largest self-propelled boom with a lift height of 135 feet.<br />

Light Hire<br />

joins<br />

<strong>Access</strong> Link<br />

The Platform Company<br />

has ordered over a 1,000<br />

new Genie aerial lifts<br />

A new Genie Z135/70<br />

arrives at Nationwide<br />

The <strong>Access</strong> Link, the UK<br />

association of independent<br />

powered access rental<br />

companies has agreed<br />

that AMP will leave the<br />

Link, now that it is part<br />

of the Lavendon group<br />

(see page 6). Light Hire<br />

Ltd, the Exeter based access rental company will replace AMP in the<br />

South West region, while other applications are being considered to<br />

fill gaps left by Panther’s departure in February.

Scaffold replaced with<br />

mast climbers<br />

All of the façade scaffold has<br />

been removed from the site of<br />

the massive scaffold collapse in<br />

April. The incident at the Jurys Inn<br />

site, in central Milton Keynes,<br />

injured three, one of whom died<br />

later in hospital. With up to 200<br />

men on the premises it could<br />

have been much much worse.<br />

After months of disruption as<br />

the HSE conducted a detailed<br />

investigation and the debris<br />

was cleared, the contractor has<br />

removed all of the scaffold and<br />

was last week installing a series<br />

of mast climbing work platforms.<br />

The Tanfield Group, which completed<br />

its acquisition of the UpRight powered<br />

access business on June 12th, has<br />

secured a £1.95 million grant from<br />

regional development agency<br />

One North East, to help fund a new<br />

production plant in the north east.<br />

The company has signed a long-term<br />

lease on Vigo 250, the former LG<br />

Electronics plant in Washington,<br />

Tyne and Wear. The facility is<br />

expected to generate around 400<br />

new jobs over the next three years.<br />

The facility is one of the largest in<br />

the region, with over 23,000 square<br />

metres (250,000 sq ft) under cover<br />

on a 15 acre (6 ha) site.<br />

The contract was initially scheduled for<br />

completion by the end of June, but as<br />

our photos show, it is still well away<br />

from completion. The cause of the collapse<br />

has resulted in much finger pointing<br />

and muck raking, until the HSE report<br />

we will not know for sure what caused it.<br />

Mast climbers<br />

are installed in place<br />

of façade scaffold in<br />

Milton Keynes<br />

Higher Platforms add<br />

Manitou mast booms<br />

Higher Platforms has purchased<br />

seven, eight metre platform height<br />

Manitou 105VJR mast booms from<br />

Russon <strong>Access</strong>.<br />

Lee Farmer, managing director said:<br />

“The new working at height regulations<br />

made a significant impact in 2005,<br />

particularly with the lower work height platforms<br />

which are replacing aluminium towers and scaffolding<br />

resulting in greater end-user safety and cost savings”.<br />

The new lifts will be based at Higher Platforms’ four depots<br />

located at Cannock, Wellingborough, Thirsk and Basildon.<br />

One of the 8m Manitou mast booms<br />

inset: Lee Farmer of Higher Platforms<br />

UpRight Production to move to UK<br />

The The new new 23,000sqm 23,000sqm<br />

plant plant for UpRight UpRight<br />

and and Aerial Aerial<br />

Darren Kell, business development director<br />

at Tanfield, told C&A that UpRight products<br />

would initially be dual sourced from the current<br />

plant in Ireland and the new facility in the<br />

UK. He also said that ideally demand would be<br />

such that both plants would run alongside<br />

each other and be kept fully employed. The<br />

new UK facility however has enough space,<br />

once it is fully functional, to keep pace with<br />

UpRight’s likely capacity demands over the<br />

next few years.<br />

Ron Stanley, chief executive and chairman<br />

of the Tanfield Group, said: “Our vision has<br />

always been to build a global manufacturing<br />

business with the North East as its heartland.<br />

We are living proof that manufacturing<br />

in this region is not dead and buried.<br />

Companies can still be profitable and<br />

competitive, provided they continue to add<br />

value. This move will see the flagship<br />

Vigo 250 facility, one of the largest<br />

manufacturing sites in the region, brought<br />

back into use, thanks to the assistance<br />

we received from One North East.”<br />

• the original & the best<br />

• 50+ years experience<br />

• extensive product range<br />

• dedicated design team<br />

• ISO & EN certified<br />

• WHAR Compliant<br />

o n a l l r i b - g r i p j o i n t s<br />

y e a r g u a r a n t e e<br />

tel: +353 1 6209 324<br />

fax: +353 1 6209 301<br />

The Best Aluminium Tower<br />

Systems in the industry...<br />

www.uprighteuro.com<br />

June July 2006 cranes & access<br />

11

working at height?<br />

Street<br />

lighting pack<br />

Telescopic<br />

Boom models<br />

12 cranes & access June July 2006<br />

Up to 23m Insulated<br />

models<br />

Jackless<br />

models<br />

360º<br />

continuous<br />

we’ve got it!<br />

van mounted<br />

access platforms<br />

www.versalift.co.uk<br />

1 Altendiez Way, Latimer Park,<br />

Burton Latimer, Northants. NN15 5YT.<br />

Tel: 01536 721010 Fax: 01536 721111<br />

email: sales@versalift.co.uk<br />

The new Liebherr LTM1300-5.1<br />

Crawler lifts the 110 tone LTR1100<br />

telescopic crawler with ease<br />

Liebherr to launch<br />

new 130 tonner<br />

Liebherr has announces that it is working on a new five axle 130 tonne<br />

All Terrain crane with a 60 metre main boom and 19m bi-fold<br />

swingaway extension. The LTM1300-5.1 will have a 12.26 metre<br />

long, 2.75 metre wide carrier and can travel with nine tonnes of<br />

counterweight within 12 tonne axle loadings.<br />

The news was released at a major series of open days held at its Ehingen<br />

plant to show off its big new crawler crane, the 1,350 tonne LR11350 with<br />

228 metre maximum tip height and relatively easy transportation capability<br />

with no single part being heavier than 45 tonnes or wider than 3.5 metres.<br />

Terex releases specs on AC100/4<br />

At Intermat, both Terex-Demag and Grove announced four axle, 100 tonner<br />

All Terrain cranes, joining Liebherr’s LTM1100-4.1. Terex has now<br />

announced the preliminary specifications for its new model which will begin<br />

shipping in 2007. The key attributes of the new crane are its narrow width<br />

of 2.55m and short overall length of 13.1m. Unlike the Liebherr and the new<br />

Grove, the Terex 50 metre main boom, while two metres short, will be a<br />

five section rather than six, making it faster to full height. Squeezing 50<br />

metres into a 13.1m length is quite an achievement, obviously saving<br />

weight and cost. The AC100-4 offers excellent duties on its full 50 metre<br />

boom, of 12 tonnes at a 10 metres radius. Leaving plenty in hand for tower<br />

crane erection work. Where the AC100/4 is really likely to score is on taxi<br />

crane work, it can carry six tonnes of counterweight, its 19 metre boom<br />

extension, blocks and equipment within 12 tonne axle loads. Add this to<br />

the 2.55m overall width, tight superstructure tail swing and four position<br />

outrigger settings and it looks like a handy crane for smaller fleets.<br />

"How does it stack up?"<br />

Make Model Main Boom Cap. Max Full Bm Length Length OAL<br />

Boom Ext 100t@ @10m @10m OAL Carrier Width<br />

Demag AC100-4 50m 19m 3m 30.3t 12t 13.1m 10.4m 2.55m<br />

Liebherr LTM1100-4.1 52m 19m 2.5m 28.7t 10.7t 13.05m 10.5m 2.75m<br />

Grove GMK4100 52m 17m 3m 29t 9.3t 13.2m 10.6m 2.75m<br />

A cad drawing of the new Demag AC100-4

Allan <strong>Access</strong> believe this is<br />

the first 20m boom on a Transit chassis<br />

First 20m boom on a Transit?<br />

Allan <strong>Access</strong> is set to deliver what it says is the first 20 metre platform<br />

to be mounted on a Ford Transit 350 chassis. The machine, fitted<br />

with a fully hydraulic Apache DA20 unit, has been sold to industrial<br />

maintenance company WB Services. It has an outreach of nine metres<br />

with 200kg in the basket. The outreach improves to 10 metres with<br />

120kg in the platform.<br />

"The customer has a fleet of Transits and asked if we could supply the<br />

platform on a Transit chassis," said managing director Phil Allan. "With help<br />

from the engineering department we have produced a vehicle that can also<br />

carry 250kg and still is under the unit's 3500kg gross vehicle weight.<br />

As far as I know, this is the first 20 metre platform on a Transit."<br />

Leith docks fined £200k<br />

The owner of Leith docks in<br />

Scotland, was fined £200,000 in<br />

June for breaching health and<br />

safety laws after a worker was<br />

hit by a crane. Robert Harrower,<br />

56, was left with injuries to his<br />

left shoulder, arm and right thigh<br />

and was off work for a week<br />

after he was struck by the crane<br />

he was inspecting. Forth Ports<br />

plc pleaded guilty to a breach of<br />

the Health and Safety at Work<br />

Regulations after the accident<br />

on December 16, 2004.<br />

The company admitted that it<br />

had failed to assess the risks to<br />

employees involved in the<br />

recommissioning of crane number<br />

42. Forth Ports had two previous<br />

convictions for breaches of the<br />

Health and Safety Act in the past<br />

four years, one of which was fatal.<br />

Harrower was hit by a bolt on the<br />

drive shaft, which was apparently<br />

not guarded. In handing down the<br />

£200,000 fine, judge Sherrif Poole<br />

said she had taken into account<br />

that the company had admitted<br />

its guilt, that the situation<br />

regarding the guard had been<br />

remedied and that Harrower had<br />

made a full recovery.<br />

New mini cranes from IMAI<br />

IMAI, the Italian producer of customised mini cranes, is launching what<br />

it is calling the Jekko range of mini cranes, with lift capacities ranging<br />

from 1.3 tonnes to 10.5 tonnes. The range will include five models.<br />

Further details will be available early next month. The mid-range models<br />

are likely to be based on the SPD260, but with improved lifting capacities.<br />

The new IMAI<br />

Jekko SPD265C<br />

June July 2006 cranes & access<br />

13

UK Distributor:<br />

King Highway Products Ltd<br />

Riverside Market Harborough<br />

Leicestershire England LE16 7PX<br />

Tele: 01858 467361<br />

Fax: 01858 467161<br />

E-Mail: sales@skyking.co.uk<br />

14<br />

cranes & access June July 2006<br />

• Self-Propelled<br />

• Vehicle Mounts<br />

• Trailer Mounts<br />

• Specials: ATEX<br />

machines and<br />

Rail Mounts<br />

Holy orders<br />

<strong>Access</strong> Rentals Ltd has taken delivery of the first<br />

batch of Basket RQG12 and 15, 12 and 15metre<br />

working height spider type tracked booms, supplied<br />

by Promax <strong>Access</strong> Ltd. One of the first jobs<br />

involved cleaning and maintenance work within a<br />

church, where the light weight, narrow dimensions<br />

and quiet fume free power, proved ideal.<br />

120 attend first German safety day<br />

120 aerial lift users and professionals attended the first Tag der<br />

ArbeitsBühnenSicherheit, TABS for short, at the Frankfurt airport<br />

conference centre on June 13th. The day was organised by the<br />

Vertikal Press, publishers of Cranes & <strong>Access</strong> and IPAF. The wide<br />

variety of speakers ensured the event was a success to the point<br />

where it looks like becoming an annual event.<br />

<strong>Access</strong> Rentals has ordered<br />

a quantity of Basket RQG<br />

spider type lifts from dealer<br />

Promax <strong>Access</strong>.<br />

The lifts feature bi-energy power units in order to cover both the construction industrial and<br />

specialist market sectors that require narrow lightweight boom lifts. The machines will be held<br />

at key regional locations to enable effective coverage of the <strong>Access</strong> Rentals depot network.<br />

ABS<br />

First mobile folding tower crane in Denmark<br />

Spierings has delivered, what it claims is the first mobile folding tower crane in Denmark, and<br />

the first Spierings crane in Scandinavia, to Odense based BAS Kraner ApS, The model is an<br />

SK599-AT5 with 50 metre jib length and maximum hook height of 56.3 metres. BAS owner,<br />

Bo Anker Schou, says that the crane is ideal for the city of Odense, which has a good number<br />

of narrow city streets with medium rise buildings.<br />

Vanson Cranes has launched the Raimondi MRT243 topless tower crane which features a<br />

new trapezoidal profile jib and double jib joints for extra rigidity and reduced jib torsion<br />

due to reduced wind effect.<br />

The crane has a maximum free standing mast height of 95 metres and offers a jib length of up to<br />

80 metres. The erection procedure has been simplified, thanks to a modular concept that combines<br />

the back jib, slew ring, hoists, slew motors, electrics and operators cabin in one complete<br />

section. The jib can either be erected in one lift, or in individual sections when space is limited.<br />

l<br />

TAG DER ARBEITSBÜHNENSICHERHEIT<br />

Trapezoidal top<br />

slewer from Vanson<br />

The new Vanson Topless MRT243<br />

features a trapezoidal jib

News HIGHLIGHTS<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

HMF has appointed Richard<br />

Everist (40) as managing director<br />

of its UK distribution subsidiary,<br />

HMF (UK), with the objective to<br />

aggressively expand the company’s<br />

share of the British market.<br />

Richard<br />

Everist<br />

Aichi has opened a North American headquarters<br />

office in Glen Burnie, Maryland. Alan Dotts<br />

has been named as general manager of Aichi<br />

USA, with responsibility for sales and support<br />

throughout the United States and Canada.<br />

Manlift the Cork based access rental company<br />

owned by Frank Delaney has opened a new<br />

branch, its third, in Galway.<br />

Cranes UK the UK distributor for Tadano Faun<br />

is relocating to new premises on Wentworth<br />

Industrial Park in Tankersley, South Yorkshire.<br />

The Manitowoc crane group has appointed<br />

John Lanning as director of advanced<br />

engineering and products for the Americas<br />

region. He will report to John Wheeler<br />

executive vice president Americas.<br />

Speedy Hire, the UK tool and equipment rental<br />

company, has joined the Financial Times Stock<br />

Exchange top 250 shares index. The group’s market<br />

capitalisation has now reached £400 million.<br />

Manitowoc has increased its second quarter<br />

and full year profits forecasts, upgrading its<br />

top end earnings expectations for the year<br />

from $2.50 to $2.60 a share. 16 percent up<br />

on its initial expectations.<br />

The rescue of Effer Holding by CTE and the<br />

company it established to take over the loader<br />

crane and platform business, SOL-Ge spa,<br />

completed the process with creditors on June<br />

28th and will now move to the second phase<br />

of production rationalisation.<br />

A 50 year old lorry loader driver was killed on<br />

July 4th, when the boom of his crane struck an<br />

11,000 volt power cable in north Essex, while<br />

unloading a flat pack shed.<br />

This years Crane safety conference in<br />

London attracted over 140 delegates, the best<br />

attendance in at least three years. Delegates<br />

attended from as far afield as New Zealand.<br />

South African Port Operations, the terminal<br />

operating division of South Africa’s transportation<br />

conglomerate, Transnet, has ordered<br />

12 all-electric E-One cranes from Kalmar.<br />

Maxim Crane Works has announced that<br />

it is exploring alternatives which include a<br />

possible merger or sale of the business, having<br />

successfully exited chapter 11 in 2004.<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Thomas Equipment has terminated its president<br />

and chief executive officer, Clifford Rhee “for<br />

cause”. The board of directors also approved<br />

“a broad-based restructuring to evaluate all<br />

corporate business activities, identify any<br />

operating and management deficiencies and<br />

immediately begin addressing all issues”.<br />

Gladedale Capital has purchased the first 50<br />

metre Teupen Leo 50GT in the UK from Ranger<br />

Equipment its UK/Ireland distributor. The lift<br />

will be used on a large, new office, retail and<br />

residential development, delivery is scheduled<br />

for next February.<br />

Holland-Lift expects to open its new 2,500<br />

square metre, sub assembly facility in Hoorn<br />

later this month. The company is planning to<br />

double its current capacity.<br />

Palazzani has formally appointed its long term<br />

UK sales partner, PASS as its dealer for the UK<br />

and Ireland for its Ragno/Mantis line of crawler<br />

mounted spider lifts and more recent mini crane<br />

line. cementing a relationship with PASS principal,<br />

Phil Lomax that dates back to the early 90’s.<br />

Insul 8 a leading player in harbour crane<br />

electrification and data transfer systems has<br />

changed its name to Conductix.<br />

A 30 ton Grove RT530 Rough Terrain crane<br />

tipped over onto its side blocking Interstate 25<br />

near Colorado Springs in early June. A similar<br />

incident with the same crane occurred eight<br />

weeks earlier on April 25th, when operator<br />

Humberto Rodriguez, 30 was killed.<br />

MEC Europe has appointed H.A.B. Service<br />

Centre GmbH as a dealer in Germany.<br />

Lloyds British Testing, the lifting equipment<br />

specialist is acquiring the goodwill and assets<br />

of Rota Handling of Dudley, from managing<br />

director Ian Payne, for an undisclosed sum.<br />

Bavarian based tower crane manufacturer, Jost<br />

Cranes GmbH, has agreed a deal with Dutch<br />

sales and rental company Kranenbouw to<br />

produce the Jost series JT 112.8 tower crane<br />

under an OEM licence.<br />

PAT has restructured its load moment indicator<br />

retrofit business. In future this business will be<br />

carried out by its international dealer network.<br />

JLG has promoted Israel Celli<br />

from vice president to senior vice<br />

president, international market<br />

development and sales,<br />

effective June first<br />

Israel Celli<br />

c&a<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

news<br />

Three men died in early June at a<br />

Volkswagen plant in Uitenhage, South Africa.<br />

When a tower crane collapsed while being<br />

dismantled by Crane Plant Services.<br />

Vertikal.net passed the 40,000 visitors a<br />

month level in May, with over 1.1 million hits.<br />

Scott McCall, previously the marketing<br />

manager at Nationwide <strong>Access</strong> has moved to<br />

the manufacturing sector, joining Van mounted<br />

aerial lift producer Gardner Denver.<br />

Neff Corp the Miami-based rental company<br />

the ninth largest in the USA, has filed plans to<br />

go public again, almost a year after it was<br />

acquired by Odyssey Investment Partners<br />

LLC, a New York based private equity firm.<br />

CRMS the Newton Abbot based distributor,<br />

which claims to be the largest Case dealer in<br />

Europe, appointed an administrator on June 1.<br />

The company has over 100 employees<br />

operating from six depots.<br />

AJ <strong>Access</strong><br />

Platforms has<br />

appointed Neil<br />

Wilkinson and<br />

Mike Palmer to<br />

help step up the<br />

company’s new<br />

and used sales<br />

efforts in the UK.<br />

Neil Wilkinson (L)<br />

and Mike Palmer<br />

Favelle Favco Bhd, the crane maker that also<br />

owns Kroll tower cranes, currently a wholly<br />

owned subsidiary of Muhibbah Engineering<br />

(M) Bhd, is set to be listed on Bursa<br />

Malaysia’s ‘second board’ in August.<br />

The Irish Health and Safety Authority is<br />

investigating the death of a 55-year-old<br />

photographer employed by Roadbridge.<br />

He was using a Telescopic handler fitted<br />

with a five metre long home made basket<br />

to photograph construction on the new<br />

Mitchelstown relief road, when it overturned.<br />

23 employees died in the Irish construction<br />

industry in 2005, up from 15 in 2004 and 20<br />

in 2003. However the number of non fatal<br />

accidents dropped by over four percent in<br />

the same period.<br />

NES Rentals Holdings, Inc, (National<br />

Equipment Service) of the USA, one of the<br />

worlds largest aerial and general equipment<br />

rental companies has announced that it has<br />

signed a definitive agreement to be acquired<br />

by Diamond Castle Holdings, LLC, a New<br />

York-based private equity firm.<br />

See www.vertikal.net news archive for full versions of all these stories<br />

June July 2006 cranes & access<br />

15

The fleet of a<br />

1,000<br />

cranes<br />

High profile companies such as Travis Perkins are under constant pressure<br />

to comply with every rule and regulation. Mark Darwin speaks with Graham<br />

Bellman on the pressures and challenges facing one of the UK’s largest<br />

lorry crane operators, where compliance is often just the starting point.<br />

Travis Perkins - TP - just keeps<br />

on expanding. One of the ‘big<br />

three’ building suppliers in the<br />

UK (along with Jewson and<br />

Wolseley UK), TP has recently<br />

opened its 1000th branch<br />

– a significant milestone for<br />

the company.<br />

Over the past five years the company<br />

has almost doubled its number of<br />

depots through acquisitions and<br />

brownfield development of<br />

new businesses.<br />

The size of the business is impressive<br />

- more than 15,000 employees and<br />

a fleet of 2000 vehicles, 2500<br />

forklifts and 1400 cars. TP also<br />

runs more than 1000 lorry mounted<br />

cranes – a significant proportion<br />

(85 percent) being Atlas units.<br />

“Over the last 10 years, Atlas<br />

has effectively been our sole<br />

lorry loader supplier,” said group<br />

transport manager Graham Bellman.<br />

“Due to the various company<br />

acquisitions, we have had many<br />

different marques. If in good<br />

working order, the machines are<br />

added to the fleet and evaluated<br />

over a period of time.”<br />

Bellman has purchased some<br />

Palfinger units for certain projects,<br />

but has also ‘acquired’ Fassi, Hiab<br />

and Bonfiglioni units. “It is hard to<br />

beat the overall Atlas package”,<br />

he says.<br />

As transport manager, Bellman has<br />

many years experience with lorry<br />

loaders and has a simplistic view<br />

of what he requires from a crane.<br />

“Lorry loaders are operated by<br />

truck drivers – so keep it simple<br />

and don’t complicate things,”<br />

c&a<br />

he said. “Basically our only<br />

stipulation is that the crane should<br />

not be able to slew over the cab<br />

roof. Maintenance of the unit and<br />

support from the manufacturer or<br />

supplier is also very important.”<br />

Having such a high profile within<br />

the industry, TP cannot afford not<br />

to comply with every rule and<br />

regulation. “If a local builder’s<br />

merchant has a problem with a<br />

delivery or a minor accident, it is<br />

probably not even reported and<br />

quickly forgotten. However if it<br />

involves Travis Perkins, then, as<br />

a publicly quoted company, it<br />

is much bigger news.”<br />

One of the older, lever operated<br />

Atlas 3008 units superseded by the<br />

3500/A11 and now the 92.2/A11<br />

lorry loaders<br />

Graham Bellman, Travis Perkins<br />

group transport manager<br />

over a trial period, we found that<br />

by operating the crane remotely<br />

it eradicated the falls. It also made<br />

the operator’s job much easier and<br />

gave a far better image to customers.”<br />

TP was the first major company<br />

to specify radio remote controls<br />

as standard on all new lorry loaders<br />

and now has more than 200 units<br />

in operation.<br />

“We have very few problems with<br />

the equipment and the operators<br />

find it much easier to unload,” said<br />

Bellman. “With 1050 lorry loaders<br />

in the current fleet, if there is a<br />

problem, we see it very quickly.”<br />

“We have more training<br />

videos than Blockbuster!”<br />

Always complying and often far<br />

exceeding what is required has<br />

resulted in TP leading the way in<br />

certain safety related areas. And<br />

it is currently looking to try and<br />

introduce more ‘logical thinking<br />

and cost saving’ in the near future.<br />

“One of the major health and safety<br />

problems we have had over the<br />

years with the lever operated lorry<br />

loaders was that the driver<br />

occasionally fell off the back of the<br />

vehicle,” said Bellman.“After testing<br />

more than 100 radio remote units<br />

“Obviously training drivers to operate<br />

the cranes is very important,” he said.<br />

“We have more training videos<br />

than Blockbuster! All employees<br />

are trained to a high level and the<br />

driver/crane operators have to sign<br />

to say they have watched and read<br />

all the relevant training information.<br />

We also outsource training to Eldon<br />

Training Services – the first ALLMI<br />

accredited training provider - to<br />

ensure that everyone is fully up<br />

to speed with operating the<br />

equipment and complying with<br />

all the latest legislation.”<br />

LOLER and PUWER regulations<br />

mean that forklifts and cranes have<br />

to be regularly inspected.<br />

June July 2006 cranes & access<br />

17

New from Hitachi Sumitomo<br />

The New SCX400T, 40 Tonne<br />

Telescopic Crawler Crane<br />

•4 Stage 32 metre boom<br />

•Wylie 3000 series total<br />

moment limiter<br />

•Retractable undercarriage<br />

•Joystick controls<br />

•Air conditioned cab<br />

•Isuzu engine<br />

For further<br />

information<br />

18 cranes & access June July 2006<br />

Official UK<br />

Distributor for<br />

The New ZX160, 8 Tonne<br />

Telescopic Crawler Crane<br />

•4 Stage 13 metre boom<br />

•Wylie 2245 series total<br />

moment limiter<br />

•Joystick controls<br />

•Air conditioned cab<br />

•Isuzu engine<br />

Hitachi Construction Machinery Tel: +31 (0) 162 484 484 Fax: +31 (0) 162 484 601 web: www.hcme.com<br />

NRC Plant Ltd Tel: +44 (0) 1375 361616 Fax: +44 (0) 1375 361818 e-mail: sales@nrcplant.co.uk web: www.nrcplant.co.uk

TP equipment has a total of five major<br />

inspections per year and this includes<br />

three maintenance inspections.<br />

“We have five, fully qualified<br />

engineers in the transport<br />

department, one of which is a<br />

specialist in lorry cranes and truck<br />

bodies,” said Bellman. “Any cranes<br />

the company acquires are fully<br />

inspected and tested to evaluate<br />

whether they are worth adding<br />

to the fleet.”<br />

Support is key<br />

According to Bellman, maintenance<br />

is the key with lorry loaders and, he<br />

says, probably the reason why he<br />

prefers Atlas loaders. Atlas claims<br />

to have 37 directly employed<br />

engineers in the UK, including<br />

four in Scotland, giving, it says,<br />

unrivalled support.<br />

All equipment will have a problem<br />

at some time or other and from the<br />

customer’s point of view, it is how<br />

quickly the supplier can send an<br />

engineer and how quickly parts can<br />

be sourced and fitted says Atlas.<br />

“Atlas builds its own cranes and so<br />

has the knowledge and expertise to<br />

identify the problem, source the<br />

parts and have the unit back in<br />

operation as soon as possible,”<br />

said Lee Maynard, general sales<br />

manager UK for Terex Atlas lorry<br />

cranes. “Even responding to problems<br />

Service in central London is just 35 minutes<br />

away using the Rapid Response motorbike<br />

in London has been sorted with<br />

the introduction of the Atlas rapid<br />

response motorbike that can be<br />

with a customer anywhere in the<br />

capital within 35 minutes.”<br />

This backup appeals to Bellman,<br />

but he also likes the ruggedness<br />

and reliability of the Atlas<br />

equipment helped, he says, by<br />

not being over complicated.<br />

“Of the other makes of equipment<br />

in the fleet, we have had faults,<br />

Radio remote controls<br />

improve safety, easy of<br />

operation and image<br />

often electronic or there is not good<br />

enough backup,” said Bellman.<br />

“Atlas currently has the best<br />

combination of performance,<br />

reliability and backup.”<br />

Current TP policy is to buy its lorry<br />

loaders and trucks (predominantly<br />

DAF) outright and run them over<br />

eight years. All new units have<br />

their PDI (pre delivery inspection)<br />

carried out by Atlas with the<br />

weight test carried out by the<br />

fitting specialist.<br />

Every effort is made to reduce the risk<br />

of an accident<br />

Its ‘bread and butter’ unit is the Atlas<br />

92.2/A11 fitted either to an 18 tonne<br />

GVW or 26 tonne with short body.<br />

This model superseded the 3500/A11<br />

and depending on the specification<br />

has a maximum load capacity of<br />

910 kg at a reach of 9.1 metres.<br />

Other units supplied include the<br />

45.2/A1 fitted to a 7.5 tonne, the<br />

85.2/A1 on a 15 tonner, the 105.2/A11<br />

on an 18 tonner timber specification<br />

truck, the 120.2/A2 fitted to a 26<br />

tonne long body and the 125.2/A2<br />

on a 32 tonne GVW. With the<br />

exception of the small 45.2, all<br />

are fitted with radio remote and<br />

Kinshofer brick grabs.<br />

c&a<br />

Specialising in heavy<br />

building products, Keyline<br />

joined the Travis Perkins group in 1999<br />

One of Bellman’s problems is the<br />

huge range and variety of products<br />

- in all shapes, sizes and weights -<br />

supplied by TP. This means that<br />

the cranes have to be specified<br />

to cover the ‘heaviest weight’<br />

carried by the truck.<br />

With material supply now a global<br />

business, packaging is generally<br />

standardised – the result of positive<br />

communication between equipment<br />

and materials suppliers.<br />

Packaging of materials has changed<br />

enormously over the years.<br />

TP now no longer supplies loose<br />

aggregate – everything is delivered<br />

in bulk bags holding a minimum<br />

of 850kg (not 1 tonne!). Liaison<br />

between the materials and<br />

equipment manufacturers ensures<br />

that packs are of a manageable<br />

size and weight. However, there<br />

are occasionally a few problems.<br />

“About six years ago we noticed<br />

that some of our Atlas 3008 units<br />

were starting to struggle when<br />

unloading packs of plasterboard,”<br />

said Bellman. “Unknown to us, the<br />

manufacturer had made the packs<br />

bigger by adding a few extra sheets<br />

per pack. As a result we upped the<br />

capacity of the loaders, switching<br />

from the eight tonne metre 3008<br />

to the 9 tonne metre 3500”.<br />

Standardisation is important as<br />

suppliers from different countries<br />

enter the global market. More recently,<br />

bricks from a supplier in the Czech<br />

Republic were manufactured in<br />

imperial sizes resulting in a<br />

physically larger pack size that<br />

could not be lifted safely.<br />

Remote control<br />

is a big plus<br />

So is Bellman happy with his fleet<br />

of lorry loaders? Well yes and no.<br />

“Remote control is a big plus and<br />

the addition of steps at the back<br />

of the vehicles also helps reduce<br />

accidents on lever cranes,” he said.<br />

“Manufacturers have gone for the<br />

small round pads under the jack<br />

lorry loaders<br />

legs which in many situations are<br />

inadequate. We need large square<br />

pads for increased stability and<br />

reduced damage to drives etc.”<br />

TP is an active member of ALLMI<br />

and has joined the user group<br />

where it is in regular contact with<br />

other crane users in an effort to<br />

improve safety and efficiency.<br />

A change is needed<br />

“There is one area that applies<br />

to all major, national material<br />

suppliers that should be changed<br />

and will make a big difference to<br />

speed of delivery and the overall<br />

cost,” said Bellman. “As a high<br />

profile, major materials supplier<br />

in the UK, we cannot afford not<br />

to comply with every piece of<br />

legislation. It is therefore annoying<br />

when vehicles are refused entry<br />

onto sites if they do not have every<br />

single certificate to show, every<br />

time they enter”.<br />

“Why not use a recognised body<br />

such as ALLMI to carry out<br />

inspections on the larger, national<br />

suppliers to ensure they have the<br />

relevant certification, and issue<br />

a compliance disc that can be<br />

displayed in the cab window<br />

saving time and therefore money,<br />

when entering sites. There has<br />

to be some trust but TP and the<br />

other major suppliers cannot afford<br />

not to comply.”<br />

TP no longer delivers in bulk, just<br />

850kg minimum weight bags<br />

June July 2006 cranes & access<br />

19

lorry loaders c&a<br />

Available on the XS111<br />

Hiab's Automatic Duty Control -<br />

ADC - aims to improve payloads<br />

and efficiency<br />

Hiab wrings 10% more<br />

capacity from its cranes<br />

Hiab’s Automatic Duty Control - ADC - aims to improve payloads<br />

and efficiency for brick and block suppliers as well as builders<br />

and roofing merchants.<br />

Available on its most popular models - the XS111, 122 and 144 models -<br />

ADC offers the customer the option of choosing a lighter, slimmer crane<br />

with the same capacity as a larger machine.<br />

The system works by recognising that brick and block 'grab' applications<br />

differ from more arduous tool applications such as digging, eliminating the<br />

need to press down and therefore creating less stress on the boom.<br />

Hiab says that 10 years’ experience with on-board computers has highlighted<br />

that in less arduous applications the crane boom is under utilized and can<br />

cope with an additional 10 percent lift capacity. ADC also enables the<br />

on-board computer to recognise if the operator is making any mistakes<br />

which might cause additional stresses to the boom system during operation.<br />

More new models from Fassi<br />

Fassi has added a five tonne/metre<br />

crane to its light duty range.<br />

Suited to 7.5 GVW vehicles the<br />

F50A.21 weighs 605kg and has<br />

an out reach of 4.9 metres with<br />

a 960kg lift capacity. Available<br />

with up to four extensions the<br />

unit has a reach of nine metres.<br />

Options include radio remote<br />

and winch.<br />

Suited to 7.5 GVW vehicles the F50A.21<br />

weighs 605kg and has a maximum<br />

radius of 4.9 metres and a 960kg lift.<br />

Fassi says that the F50A is<br />

extremely competitively priced<br />

and includes its new hydraulic<br />

20 cranes & access June July 2006<br />

overload protection system<br />

– HO – as standard equipment.<br />

Fassi has also further extended<br />

the Evolution series, that it<br />

launched at SAIE last year, to its<br />

24 – 45 tonne/metre range of<br />

loader cranes. All Evolution cranes<br />

feature radio remote control as<br />

standard along with the Fassi ADC<br />

(Automatic Dynamic Control)<br />

system which controls the crane<br />

speed relative to the load and<br />

claims Fassi, eliminates undesirable<br />

load bouncing. As with other<br />

Evolution models, the cranes are<br />

lighter than the outgoing models<br />

and in the case of the<br />

F290A/310AXP lifting capacity<br />

has been increased by 10 percent.<br />

The Evolution visual display on the<br />

standard remote controller.<br />

New rock drill<br />

quadruples speed<br />

The Rockmaster earth drill quietly<br />

slipped onto the market when<br />

four units were specifically<br />

designed and sold to British<br />

Telecom. Drilling using loader<br />

cranes can be a particularly<br />

tedious and time consuming<br />

process. The ‘Rockmaster’<br />

however, claims to offer much<br />

higher output and reliability for<br />

concrete, tarmac or rocky<br />

conditions. Using a hydraulically<br />

driven percussion gearbox<br />

between the auger drive unit and<br />

special Rock Ripper auger, the<br />

penetration in concrete is<br />

increased from 220mm per hour<br />

with a standard unit to 800mm<br />

per hour on a standard BT Pole<br />

Erection Unit.<br />

Crane and body fitters Spenborough Engineering is keeping up with the<br />

advanced materials being used by loader crane manufacturers, by using<br />

ultra high yield crane steel on a new range of lightweight bodies. In addition<br />

to the lighter weight, critical on van chassis, Spenborough says the new<br />

steels offer increased longevity without compromising lift capacity.<br />

A recent contract for a local authority<br />

involved an Iveco 65C15 chassi fitted<br />

with a Palfinger PC1300A crane<br />

which has a maximum capacity<br />

of 1130kg at one metre radius.<br />

For increased stability, the vehicle<br />

was fitted with hydraulic stabilisers<br />

within the body width. Guarding<br />

around the crane base has been<br />

fitted for additional safety.<br />

Pesci has also introduced a<br />

13 tonne/metre, all hydraulic<br />

(no electronics) ‘old technology’<br />

crane in response to customer<br />

requests. Geoff Hindle, managing<br />

director of Manchester-based<br />

distributor Crane Sales says<br />

that on cranes of up to 32<br />

tonne/metres, customers would<br />

rather have a simple unit,<br />

without complications such<br />

as sophisticated electronics.<br />

However, Pesci has also launched<br />

the SE435 with its new CSS safety<br />

monitoring system. The system,<br />

which will be fitted in all new<br />

Pesci has introduced new all<br />

hydraulics models and a new CSS<br />

safety monitoring system.<br />

The Rockmaster auger with<br />

persussion gearbox quadruples<br />

drilling speeds<br />

Rockmaster says that tests have<br />

verified that the system imposes no<br />

extra loading on the crane structure.<br />

Surprisingly, it has been shown<br />

that loads are normally lower with<br />

the percussion system engaged.<br />

For loader cranes, no additional<br />

hydraulic services are required.<br />

When activated, the percussion<br />

action works in the forward (drilling)<br />

rotation only and automatically<br />

switches the auger drive unit to<br />

low speed for maximum torque.<br />

Body builder uses ultra high yield steel<br />

Spenborough Engineering is now using<br />

the stronger and lighter ultra high yield<br />

steel in its new range of bodies<br />

Pesci goes back to basics<br />

models, including the SE405,<br />

SE765 and the SE815, monitors<br />

the extent the crane is out of level<br />

and automatically de-rates the<br />

lift capacity.

June July 2006 cranes & access<br />

21

22 cranes & access June July 2006

Lower<br />

Lighter<br />

Smaller<br />

Cheaper<br />

The new Work at Height Rules have encouraged, or in some<br />

cases, forced, many ladder and staging users to reconsider<br />

the equipment they use to carry out routine work at height.<br />

This in turn is spurring on the development and use of a<br />

wide range of access equipment with lower heights, lighter<br />

weights, simpler construction and lower cost.<br />

The products that are beginning<br />

to come to the fore range from a<br />

wide array of podium steps up<br />

through portable push around<br />